Last we left the elevator it was half wrapped. So today we first covered the trim tab.

We didn’t do the hinge since that would have required cutting the vinyl everywhere the hinge had a gap and that just seemed too much work. It does mean the top will need a little white paint to finish it off.

The rest of the elevator followed.

Not sure you can tell from the pictures but we are getting a lot better with the wrapping and getting no blemishes – I wish we had this experience when we started. Like I often say, the next plane will be better!

Next we installed the elevator on the tail with all of the proper hardware, cotter pins etc. There should be no reason to remove it from here on.

Control cables were reattached and cotter pinned.

Alas, there was no time to start on the rudder, next time.

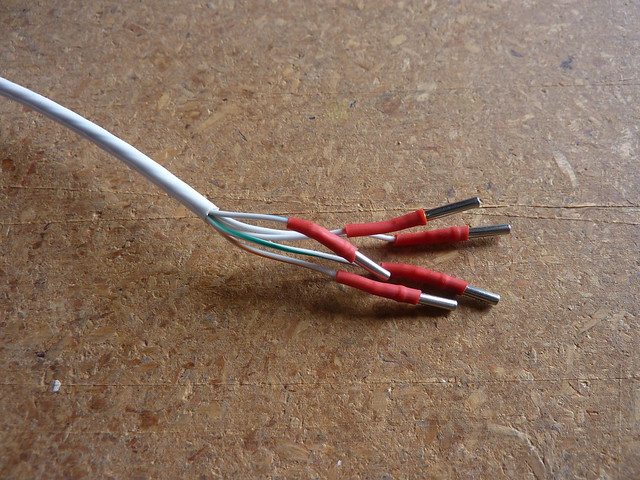

Other than vinyl I crimped the connectors onto the trim servo wire.

and joined the servo wire to the fuselage wire.

Since it was there I wrapped the top of the rudder.

I also started some work on the holes in the wings for the fuel line and electrical wires to go through the central spar and out the wing end. I enlarged the holes for the grommet but I don’t think it was enough because although I could get the grommet in, the fuel line would not.

I opened the wires hole in each spar but then could not find the grommets that fit in there. The metal is quite thick so standard ones won’t work. I couldn’t find them (probably used them for something else) so ordered new ones today.

We’re running out of time to get the wings done (and a sudden trip to Tokyo at the end of the month isn’t going to help) so I’m going to need to take some weekdays off to work with Allen before he leaves for the summer.